Computer Cutting Machine¶

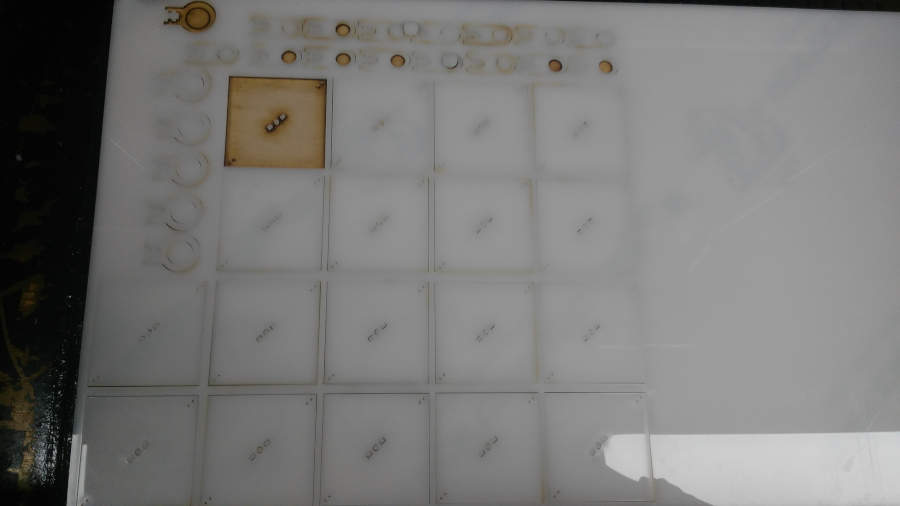

This is the end result of fabricated parts

Let’s see the fabrication process for each part…

CNC Router¶

My first fabricated started in Computer-controlled machining. The structure frame of my façade, but I don’t like the result, so I changed it with laser cutting parts.

3D Printing¶

Brackets¶

This part instead of servo brackets, it just a test to chose the default holes of screws with different tolerance

You can check the design from this link

After the integration with the panels, I decided to change the design of the fixation part and replace it with another design ‘a cylinder’. Please check the new design.

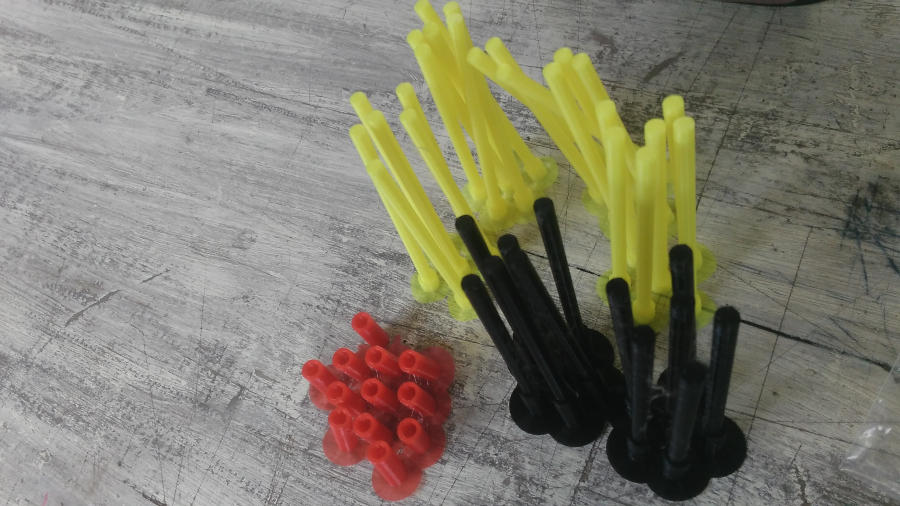

Cylinder¶

This is the first version that I have been designed.

I noticed that the yellow cylinder is not accurate in the printing process because the section of the extruded box is small and very tall, so the result is not good. Plus, when I test the press fit ‘in the yellow cylinder’ with the female part ‘silver cylinder’ I found that it’s easily broken…

So, Mahmoud Kotb advised me, that we don’t need long weak supports as much as we need small strong support…

So, I redesign this part again. You can review the design from here

Now, I made sure of this part and its structure. So, I can repeat these parts as I want … I need 24 parts from the yellow cylinder, 12 parts from the black cylinder and 12 parts from the red one. To make 12 cylinders.

The next step I used laser cutter

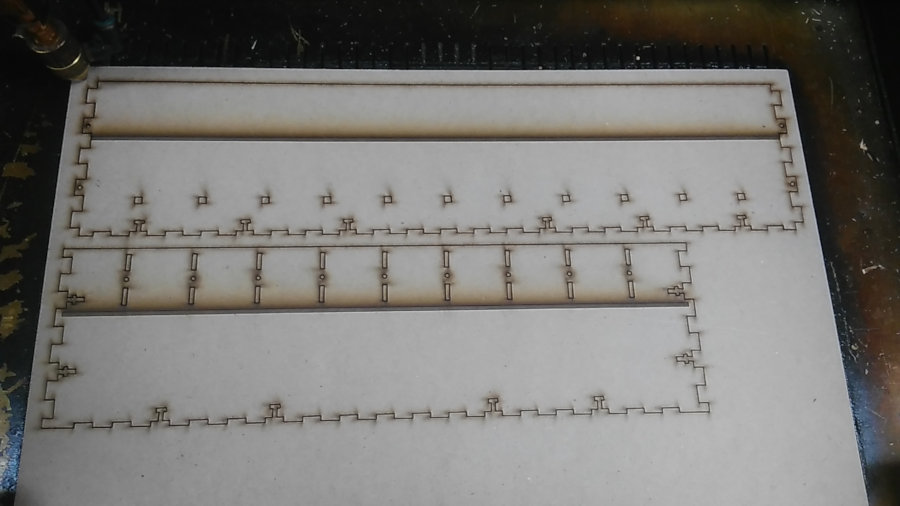

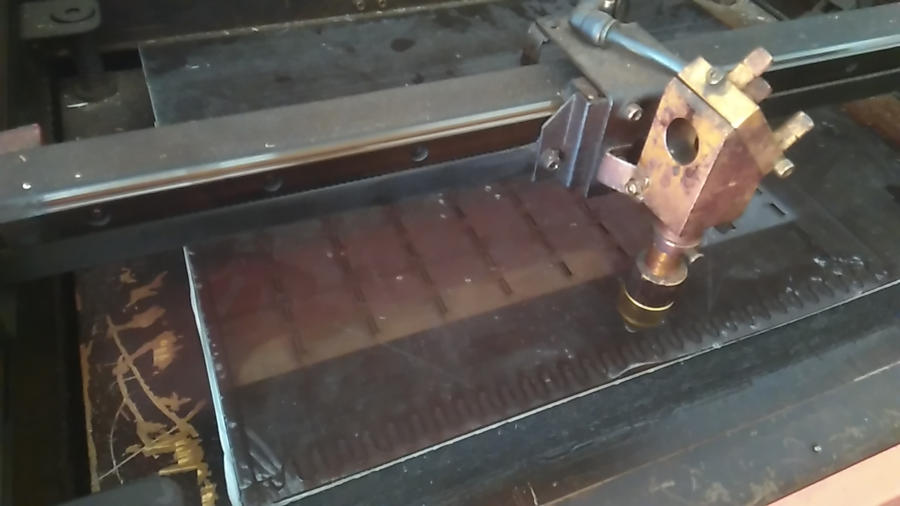

Laser Cutter¶

Usually, I started with test parts. Especially, the 3d printing cylinder … I determine it again after printing, by Caliper. It’s definitely changed with tolerance value.

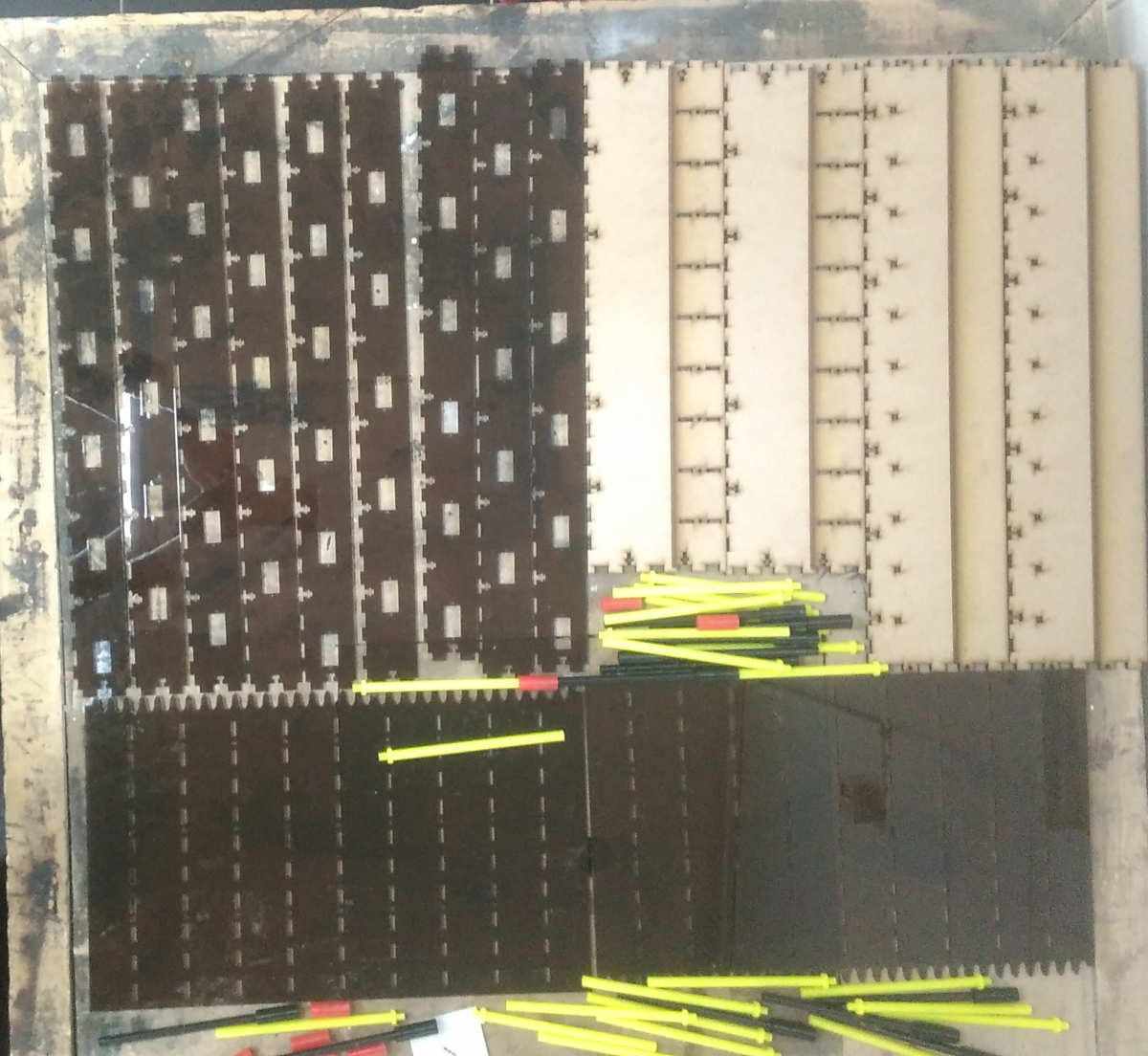

MDF 6 mm, for the façade structure¶

I cut two sheets from these parts.

Acrylic 3mm, for the servo structure¶

I have two different parts, one of them includes 5 servos and the second includes six servos. According to the diagonal pattern in the façade.

Five parts from the six servos, and four parts from five servos.

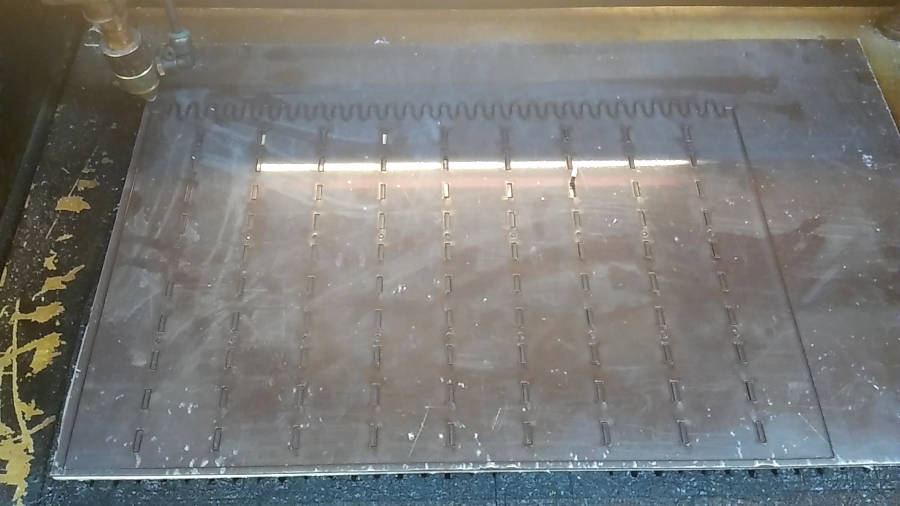

Acrylic 3mm, for the glass type¶

This part is supposed be 480 mm height * 400 mm width, and the dimensions of our machine is 300 mm * 500 mm. So I spilt this part to two parts and the press fit between them is zigzag. Also this part fixed in the servo structure parts.

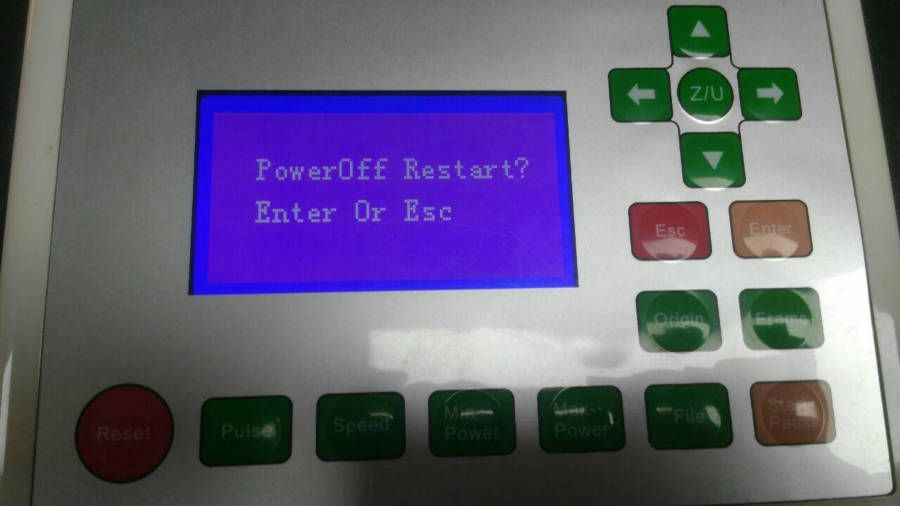

During cutting process in this stage, the power is cut off!

Fortunately, it started again from the previous coordinates. So I press ESC then started the process again from the first. Mrehan cleared me that, because the power is cut off and the PC was shut down we can’t to delete the parts that have been cut and start from the rest parts. If we made that, the machine will lose the previous coordinates.

Acrylic 2mm, for the panels¶